QUALITY ASSURANCE

Quality is all the features in the product to meet customer requirements. Quality is a multifaceted concept that describes how well a service, process, material, or product possesses desired intangible or physical attributes. CB is highly concerned about the key operations for a well, organized, planned QC inspection on every step of the RMG goods production.

- The act of overseeing all activities and tasks needed to maintain a desired level of excellence.

- This includes creating and implementing quality planning and assurance, as well as quality control and quality improvement.

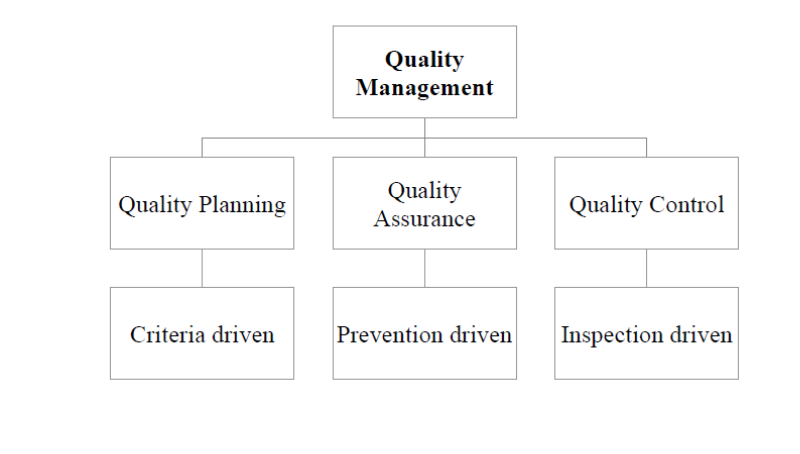

Quality Planning- Criteria Driven

- It identifies the standards and determines how to satisfy those standards.

- It lays out the roles and responsibilities, resources, procedures, and processes to be utilized for quality control and quality assurance.

Quality Assurance- Prevention driven

- It is the review to ensure aligning with the quality standards.

- Planned and systematic quality activities.

- Provide the confidence that the standards will be met.

Quality Control- Inspection driven

- It addresses the assessment conducted during Quality Assurance for corrective actions.

- Measure specific results to determine that they match the standards.

- Use of Statistical Process Control (SPC) for monitoring a process to identify special causes of variation and signal the need to take corrective action when appropriate.

The quality of a product or service is assessed based on some parameters which are termed as the dimension of quality.

- Performance

- Durability

- Aesthetics

- Features

- Serviceability

- Conformance

- Reliability

- Perceived quality.

Quality control is a continuous and regular control of the parameters which affect the quality of the final product. Quality assurance is the “process of designing, producing, evaluating, and assessing products to determine that they meet the desired quality level for a company’s target market”. Quality control is generally understood as assessing for quality after products have already been manufactured and sorted into acceptable and unacceptable categories. It is costly for companies that do not take a quality assurance method, but only look at quality in terms of quality control.

It comprises of planning, raw data compilation, its investigation and implementation. In the process of quality control, the control at various levels of production of garments is monitored by various control forms. This helps in maintaining continuity in the quality control. Further monitoring of the production process will be controlled by documentation. The stage-by-stage documentation helps in not only achieving the expected quality but also in completion of production within the target time.

Quality control is the day-to-day implementation of quality assurance, and to succeed you have to be very proactive at all levels. Quality controllers need to learn as much as they can about all aspects of the business as they will need to liaise with all departments in the company as well as customers and suppliers.

Investment in quality control is a form of insurance, but it does not wait for disaster to happen and then compensate; it works to prevent the disaster from happening in the first place. If implemented properly, it is continuously maintaining the servicing, and repairing your supply chain.

Quality control in the apparel industry can be executed by classifying the entire industry into the following sub-divisions:

- Pre-production stages

- Production stages

- Post-production stages.

1. Quality control in Pre-production:

a) Fabric quality control through assessing:

- Comfort properties

- Color fastness properties

- Durability properties

- Other technical properties such as GSM, carded/combed yarn, composition, EPI, PPI, etc.

b) Other trimmings and accessories such as:

- Closure

- Zipper, Button, Hooks, Snap fasteners, Drawstrings, etc.

- Interlinings/interfacing

- Sewing threads

- Elastic waistband

- Other design elements such as:

- Beads, Sequins, Braids, Fringes etc.

2. Quality control in Production:

- QC in Spreading

- QC in cutting

- QC in assembling parts

- QC in sewing

- QC in finishing.

3. Quality control in Post-Production/Final inspection:

- Technical parameters such as:

- Defects in yarn, fabrics.

- Defects in trims and accessories.

- Stitching defects.

- Seam defects etc.

- Performances such as:

- Overall appearance.

- Sizing and fit.

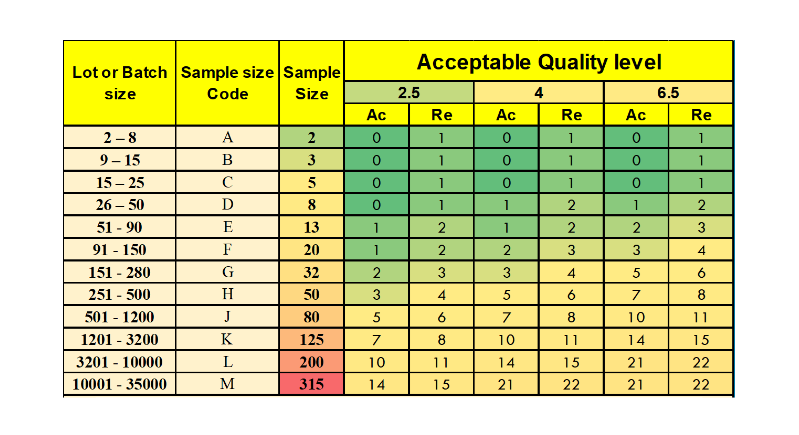

AQL is an abbreviation for Acceptable Quality Level or Acceptance Quality Level. AQL is one of the most used terms in the apparel industry when it comes to consideration to quality garment inspection. AQL refers to the maximum number of defective items that could be considered to accept during the random sampling of pre-shipment inspection. To reduce risk before accepting a shipment, AQL sampling is a practical and effective approach to undertake quality assurance on an order of produced items. Generally, for clothing items, 1.5%, 2.5%, 4.0%, 6.5%, and 10% AQL values are used depending on the type and price of the clothing.

AQL depends on the percentage of defective or defects per 100 units. Percentage defective is used in the apparel industry for simply made products, components, and materials. It is calculated by taking the number of defective products, multiplying by 100, and dividing by the number of units inspected. Defects per 100 units are a more exact way to find acceptable production lots. Defects per 100 units are calculated by taking the total number of defects, multiplying by 100, and dividing by the number of units inspected.

Before checking goods, always be prepared and have the approved sample, color swatches, specifications, and all relevant information at hand. It makes your job much easier if you are always methodical, and this applies especially to inspection. You must be meticulous but also quick if you have many deliveries to check in a limited amount of time. It is also crucial to remember that large-scale inspections are frequently expensive, unneeded, and time- consuming.

It is very unlikely that you will have a delivery with no faults, so you accept that a percentage of the production will have some major faults. The factory should always do a 100% inspection of the goods before packing and to what degree can vary from each factory (this is an important point to check when doing a factory assessment).

Often, it can just consist of trimming cotton ends and a brief glance at the garment. Other factories do a more detailed inspection. As the customer, you should not have to do a 100% inspection of every delivery, as it is very costly and time-consuming, and it is the responsibility of the factory to check that the delivery is acceptable. However, it is essential that you do a check on the goods before accepting them.

Acceptable quality level (AQL) sampling plans are an internationally adopted method of determining the level of quality of a delivery by checking a percentage of the total quantity. A sample size of garments to inspect is determined by the quantity in the delivery and then the number of faulty garments you find after the inspection that you consider acceptable. If the number of faulty garments exceeds the acceptable level, then a 100% inspection is required. The following AQL inspection chart is the most commonly used in the apparel industry.

Table: AQL inspection chart.

The AQL inspection chart was developed by the military during the World War II to check munitions and has now been adapted for deliveries of all types of products, as the level of rejection can be loosened or tightened, depending on the requirements of your business. Here, we have an example of three levels of inspection used in the textile industry, and you can see that the 2.5 level allows less faulty garments than the 4.0 and 6.5 levels. You may decide to use 4.0 AQL for all your deliveries or, for example, use 2.5 AQL for more expensive luxury items.

It is important that your factories are aware of the level of inspection you will be using when checking deliveries at your warehouse or at their factory. Ideally, the factory should do its AQL inspection on each delivery before it is shipped. It is common today for companies to use independent inspection companies or, if you have a local office, use your own representatives to do the AQL inspection at the factory before goods are shipped. If the delivery fails the inspection, it can then be rectified before shipping. Whichever method or whomever we use for the inspection, our goal is ultimately to work with factories that build in quality checks at every stage of design and production, so that an AQL on their products becomes more routine than essential.